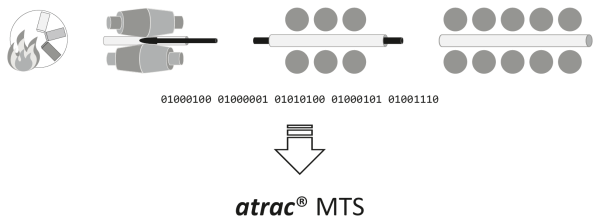

atrac® MTS gives you a better overview of the entire production line, from the furnace to the cooling bed.

To accomplish this, the rolling material is tracked and all process data is collected and continuously evaluated using technological process models. The entire production line becomes more transparent; you are actively notified in case of quality-related events.

As a result, you achieve higher product quality, security, and transparency during production.

The MTS collects the data of the aggregates along the production line:

atrac® MTS and the transparency:

Based on the collected data, atrac® MTS:

atrac® MTS and the production safety:

atrac® MTS and the product quality:

Each installation of atrac® MTS is adapted to the special requests of the rolling mill operator, with any number of connected aggregates and free selection of the data to be collected as well as their volume. The data can be retrieved by identifier per timestamp. The rolling mill operator can choose between standard reports in tabular and graphical form and custom reports designed to customer's preferences.

atrac® MTS is currently being implemented at the Bavarian Rohrwerk Maxhütte GmbH (autumn 2018). The project is expected to be completed in the first quarter of 2019.

You can find more information in the flyer. And if you have any questions or want to know more, feel free to contact us.